Five Advantages of Portable Laser Cleaning

·The pull rod design is more maneuverable, the whole machine only weighs about 25kg, occupies a small area, and is easy to move and transport.

·Efficient, non-destructive cleaning, for rust, oil, coating, oxidation and other cleaning effect is more significant.

·High cleaning efficiency, save time, no consumables, more safe and environmental protection.

·LCD touch screen, easy to operate, five minutes to get started, system stability.

·Supports 8 scanning modes, can choose a variety of cleaning shapes, suitable for a variety of materials.

·Precise cleaning, with auxiliary focusing device, used to fix the focallength during cleaning, to avoid inaccurate control of the focal lengthand slow cleaning efficiency.

·Ultra-long life, laser operation up to 100,000 hours.

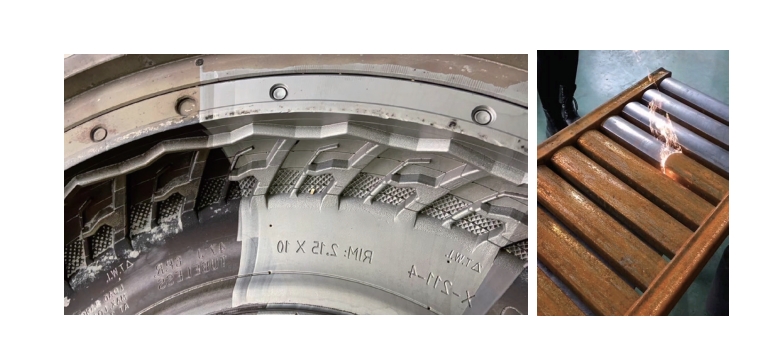

Sandblasting, chemical etching, high-pressure water jets... Traditional cleaning methods are not only time-consuming and labor-intensive but may also damage workpiece surfaces and cause environmental pollution. Leapion’s Pulsed Laser Cleaning Machine, with its unique advantages of portability, efficiency, precision, and zero damage, is becoming the new benchmark in industrial cleaning! Today, we compare laser cleaning with traditional methods to show why more and more companies are choosing Leapion!

Five Advantages of Portable Laser Cleaning

1. Lightweight and Mobile

With a pull-rod design weighing only 25kg, it can be easily transported to elevated or remote sites, solving the "difficult access" issues of traditional equipment.

2. Ready-to-Use, Extremely Simple Operation

The LCD screen pre-sets 8 scanning modes (e.g., linear, circular, linear array), requiring no professional training. Users can get started in just 5 minutes.

3. Enhanced Safety

No chemical splashing or dust explosion risks, making it suitable for hazardous environments such as petroleum pipelines.

4. Significant Economic Benefits

Taking the above auto factory as an example: laser cleaning reduced per-unit costs by 60% compared to sandblasting and eliminated waste disposal expenses.

5. Adaptable to Future Automation Trends

Can be integrated with robotic arms for smart assembly line cleaning. The software supports secondary development and can connect with MES/ERP systems.

Why Are Pulsed Laser Cleaning Machines Becoming Increasingly Popular?

Policy Drivers

Global environmental regulations are tightening, forcing companies to phase out highly polluting cleaning methods.

Breakthrough in Non-Destructive Cleaning

Pulsed laser cleaners are highly favored for their fine precision and efficient oil removal capabilities.

Micron-level precision enables non-destructive cleaning of delicate components, selectively removing contaminants without harming the substrate. Pulsed lasers thoroughly strip oils without chemical solvents, making the process eco-friendly and efficient.

Moreover, they adapt to complex structures, offer high automation, and have low long-term costs. They are widely used in electronics, automotive, cultural relic restoration, and more, becoming the preferred alternative to traditional cleaning processes.

Answers to 4 Frequently Asked Questions

Q1: Will laser cleaning damage the metal surface?

A: It does not damage the substrate itself. Pulse width is adjustable, and energy is precisely controlled.

Q2: Is the equipment lifespan really 100,000 hours?

A: Calculated at 8 hours per day ≈ 34 years. However, due to technological advancements, we recommend upgrading after 8–10 years.

Q3: How to clean complex curved surfaces?

A: 8 scanning modes + 254mm field lens perfectly adapt to irregular parts such as gears and impellers.

Q4: Are after-sales maintenance costs high?

A: Truth: Only requires monthly cleaning of the field lens. If the lens is damaged, the protective mirror needs replacement (annual cost < ¥500).

Whether it’s mold derusting or auto parts cleaning, Leapion Laser Cleaning Machine offers a perfect solution — substrate-safe, consumable-free, precise, low-cost, and eco-friendly! Say goodbye to the hassle and risks of traditional cleaning. Choose Leapion to make cleaning simpler and smarter!

Related Products

Submitted successfully

We will contact you as soon as possible