All Your Questions About Laser Cleaning Answered Here!

Water cooling, can be used in high temperature or low temperature environment, heating or cooling through the chiller to keep the equipment at the best use temperature to ensure long-term stable work.

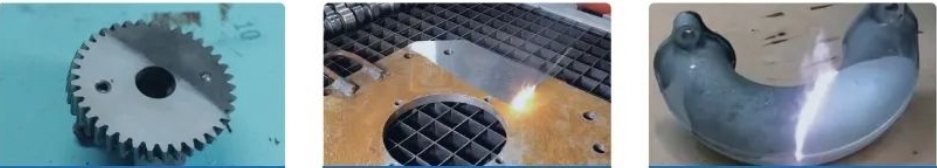

Designed for more complex, large-scale, and sophisticated surface cleaning wide range, can remove metal oxides, rust, oil, dirt, trees surface impurities such as grease, paint, post-weld black ash, welds, graffiti and coatings can be adjust different parameters, no thermal effect, will not cause any damage to the substrate.

Highly efficient and environmentally friendly, without any chemicals and cleaning fluids, no consumables, and recyclable materials after cleaning.

High cleaning efficiency, time saving, long-term stable use of the system, low operating costs.

Strong applicability and mobility, can be hand-held, can also be integrated in the automation and manipulator connection, to achieve automatic cleaning, can reach the traditional method is not easy to

clean the parts. Use in some dangerous places can ensure the safety

of personnel.

All Your Questions About Laser Cleaning Answered Here!

Tired of traditional cleaning methods that are inefficient, damage materials, and harm the environment? Leiyuan Laser Cleaning Machines offer you an efficient, precise, and zero-damage cleaning solution! Below are answers to the most frequently asked questions about laser pulse cleaning machines:

1. What are the advantages of laser cleaning machines compared to traditional cleaning methods?

Eco-friendly & Efficient: No chemicals required, no pollution, and cleaned residues can be recycled.

Non-destructive Cleaning: Causes no damage to the base material, avoiding surface wear caused by traditional methods (e.g., sandblasting, chemical etching).

Precise & Flexible: Adjustable parameters adapt to different materials and contamination types. Cabinet laser cleaners are especially suitable for precision parts and complex shapes.

2. Which industries and applications are laser cleaning machines suitable for?

Wide Applicability: Mold manufacturing, automotive repair, aerospace, electronics micro-processing, rail transportation, construction, furniture, military equipment, etc.

Typical Uses: Rust and oil removal from molds;

Cleaning of post-weld black residues on auto parts;

Aircraft coating removal;

Heritage restoration (non-contact cleaning).

3. Will laser cleaning damage the material surface?

No. By adjusting parameters such as pulse width and frequency, energy can be precisely controlled to remove only surface contaminants without harming the substrate.

4. How efficient is it? Are consumables needed?

Highly Efficient: For example, cleaning 10cm² of rust takes only seconds to minutes (depending on power and contamination thickness).

Zero Consumables: No need to purchase chemicals or abrasives, resulting in lower long-term costs.

5. Is it difficult to operate? Is professional training required?

User-Friendly: Equipped with a touchscreen LCD supporting 8 scanning modes; beginners can learn within 5 minutes.

Assistive Features: Fixed-focus devices and preset parameter templates further reduce the learning curve.

6. What is the equipment lifespan and maintenance cost?

Long Lifespan: Laser source life reaches 100,000 hours, with very low daily operating costs.

Low Maintenance: Stable air/water cooling design; daily maintenance only requires lens cleaning.

No vulnerable parts—maintenance costs are just 1/5 of traditional equipment.

7. How to choose the right laser cleaning model?

For Portability:

Trolley-style (25kg): Highly mobile, excellent heat dissipation, ideal for confined spaces like mold and auto repair workshops.

For Industrial Use:

Cabinet water-cooled (300W-1000W): Suitable for large-scale precision cleaning in aerospace, shipbuilding, etc.

8. How is after-sales service supported?

Leiyuan Full-Cycle Service: Pre-sales technical consultation, operational guidance during sales, and 24/7 after-sales support.

Global Network: 200+ service points in China; certifications include EU CE, UL, and US FDA for worry-free quality.

Related Products

Submitted successfully

We will contact you as soon as possible