Mobile 'Marking Master' creates high-quality precision identification for automotive parts

1.Upgraded power to 60W, achieving finer marking effect and significantly improving operational efficiency

2.Innovative protective javelin head, certified by EU CE to ensure safe operation

3.Equipped with a self-developed Linux system and a 7-inch high-definition touch screen, the operation is smooth and the response is fast

4.Open software architecture, supporting seamless integration of industrial systems such as MES/ERP/PLC

5.Multi device interconnection: compatible with keyboard and mouse/scanner/PC control, supports remote management through mobile APP

6.Modular lithium battery pack, supporting hot swappable replacement and continuous power supply working mode

7.Intelligent integration solution: Can connect robotic arms to form a fully automatic marking workstation

With the rapid development of the automotive industry, the demand for quality, safety, and efficiency in the automotive manufacturing industry continues to increase, especially for precise management and quality control of automotive components. The requirement for components to have traceability has become an industry trend. In this context, laser marking technology has become an indispensable part of the automotive manufacturing industry with its unique advantages.

The Radium Source handheld laser marking machine, with its high precision, high speed, high flexibility, and environmental friendliness, has shown broad application prospects in small batch, trial production, or SKD/CKD production environments in the automotive parts manufacturing industry.

Industry pain points and solutions

Industry pain points

Poor flexibility and low efficiency

① There are various types of automotive components with different shapes and materials, and traditional marking machines are difficult to meet the needs of multiple types of marking

② Some components have a large volume and weight, making it difficult to move them onto the workbench of a conventional marking machine.

③ The volume is too large, the total weight of the machine is about 100kg, and the transportation cost is high.

④ High quality marking equipment and technology are expensive and costly, which limits their popularity and application in the industry.

⑤ The operation is complex, and the traditional laser marking machine is connected to MES and the upper computer, requiring additional computer configuration.

⑥ Additional power connection is limited in use and requires additional power configuration for the device.

⑦ Marking errors are irreparable. Laser marking is permanent, and once an error occurs, traditional erasing methods are ineffective and may even damage the surface of the material.

Modern solutions

High precision marking, portable design

① Realize high-precision and durable marking, resistant to high temperature, chemical corrosion, and not easily worn or scratched, meeting the identification requirements of high-precision components.

② Handheld design, with a total weight of about 6kg, easy to carry and operate, and low transportation costs.

③ Easy to integrate production lines with PLC, MES, ERP, upper computer, and robotic arm, with fast marking speed and high degree of automation. (Key image with robotic arm)

high performance-price ratio

④ Ultra high cost-effectiveness, long service life, low energy consumption, optimized marking process, and low maintenance costs in the later stage.

⑤ Self developed operating system, no need for a separate computer

Comes with a 7-inch touch screen, no need for a separate computer, convenient for on-site operators to use, Simple and easy-to-use operation, while also ensuring stability.

⑥ Optional battery version, one more choiceOptional battery powered devices, with replaceable batteries that can also be plugged in for use

⑦ Paired with radium source laser cleaning machine, the effect is better

Backpack/pull rod pulse laser cleaning machine, quickly penetrates and peels off stubborn dirt such as oil stains and carbon deposits, and performs non-destructive cleaning. Two machines only cost the price of one traditional equipment.

Application scenarios

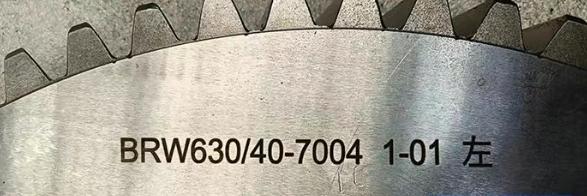

Tires, gears, bearings, car wheels, exhaust pipes, engine cylinder blocks, engine chassis, pistons, crankshafts, shock absorbers, brake discs, etc

Marking type:

QR code, barcode, clear text, production date, serial number Logo、 Pattern, VIN number, etc

Related Products

Submitted successfully

We will contact you as soon as possible