A Laser Cleaning Machine with Exceptional Value: Why It’s the Top Choice for SMEs

The pull rod design is more maneuverable, the whole machine only weighs about 25kg, occupies a small area, and is easy to move and

transport.

Efficient, non-destructive cleaning, for rust, oil, coating, oxidation and other cleaning effect is more significant.

High cleaning efficiency, save time, no consumables, more safe and environmental protection.

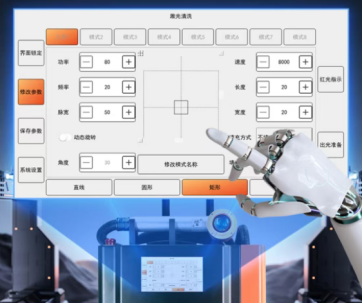

LCD touch screen, easy to operate, five minutes to get started, system stability.

Supports 8 scanning modes, can choose a variety of cleaning shapes, suitable for a variety of materials.

Precise cleaning, with auxiliary focusing device, used to fix the focallength during cleaning, to avoid inaccurate control of the focal length and slow cleaning efficiency.

Ultra-long life, laser operation up to 100,000 hours.

In a market where laser cleaning equipment often costs hundreds of thousands or even millions, small and medium-sized enterprises (SMEs) often face the dilemma of “wanting to use it but not being able to afford it.” High upfront investment, complex maintenance costs, and the difficulty of training operators—these are all real challenges businesses encounter.

However, as technology matures and mass production scales up, LZY’s Pull Rod Pulsed Laser Cleaning Machine stands out with its high cost-effectiveness, low operating costs, and extremely simple operation, making it the preferred cleaning solution for SMEs!

1. Pain Points for SMEs in Cleaning: High Costs, Low Efficiency, Complex Operation

High equipment investment: Traditional industrial cleaning machines come with high initial purchase and maintenance costs, leading to a long payback period.

Ongoing consumable expenses: Continuous costs for chemicals, abrasives, and other consumables add up.

Complex operation: Requires specialized training, and high staff turnover drives up training costs.

Inconsistent cleaning results: Traditional methods often lead to incomplete cleaning or damage to workpieces.

2. LZY Pull Rod Laser Cleaning Machine: The King of Cost-Effectiveness!

Affordable price, fast ROI: Compared to cabinet-style machines that cost hundreds of thousands, the pull rod model is more budget-friendly, with a payback period of just 6–12 months—ideal for SMEs with limited budgets.

Zero consumables, saves money long-term: No need for chemicals, abrasives, or cleaning fluids. Waste material can be directly recycled, truly offering “one-time investment, long-term benefits.”

Mobile and flexible, easy to move: Pull rod design enhances mobility. The entire machine weighs only about 25kg, occupies minimal space, and is easy to transport and maneuver.

Simple operation, trained in just five minutes: Equipped with a touchscreen LCD, multi-language interface, and preset parameter modes. Even beginners can operate it independently, reducing reliance on skilled labor.

3. Versatile Applications, One Machine for Multiple Uses

Whether it’s rust removal, oil removal, coating removal, mold cleaning, weld cleaning, or paint restoration, this machine can handle it all. With support for 8 scanning modes, it adapts flexibly to different materials and shapes.

4. Industry Application Cases

An auto repair shop: Used for vehicle paint cleaning, replacing traditional sanding methods. Efficiency increased by 50%, with no dust pollution.

A mold workshop: Cleaned release agent residue from injection molds, avoiding chemical corrosion and extending mold life.

A steel structure factory: Used for weld cleaning and pretreatment, improving welding quality and meeting environmental standards.

5. User Testimonials: Really Worth It!

"Previously, for used car paint jobs, we either sanded or used chemical stripping—dusty, smelly, and workers hated it. After switching to this pull rod laser cleaner, it’s like pushing a vacuum cleaner—just plug and play. It leaves no chemical residue and doesn’t damage the paint. Efficiency is up, we meet environmental standards, and we’re more confident taking on orders!"

— Manager Wang, Auto Repair Shop

"Our precision molds require extremely high cleaning standards. Traditional methods often cause scratches or residue. The auxiliary fixed focus feature of this machine is incredibly practical—it ensures consistent cleaning results, perfectly removes release agents without damaging the mold surface. At 25kg, it’s easy to move around the workshop. Absolutely a must-have for maintaining precision parts."

— Foreman Li, Mold Workshop

"On our construction sites, we deal with complex environments and often work at heights. This machine is lightweight, durable, and can be transported easily on a pallet. It works on-site with just a power connection. With 8 scanning modes, it handles everything from surface rust removal to complex weld cleaning. One machine for multiple uses—it really cuts our overall costs."

— Manager Wang, Steel Structure Contractor

6. How to Choose? LZY’s Recommendations

For frequent cleaning tasks in fixed locations: Choose cabinet-style water-cooled laser cleaners for higher power and stability.

For mobile use and diverse cleaning scenarios: The pull rod air-cooled laser cleaner offers portability and exceptional cost-effectiveness.

A good machine shouldn’t just clean well—it should also be worry-free, cost-effective, and easy to use. LZY’s Portable Laser Cleaning Machine is tailor-made as a high-value cleaning solution for SMEs.

Follow us for more cleaning case studies and product info.

To request a quote or industry-specific solutions, leave a message below or call our hotline: 400-0843-611.

Related Products

Submitted successfully

We will contact you as soon as possible